Products 2

Paint and Fertilizer Bags (Woven Bags)

These are durable bags designed for packaging and transporting heavy materials such as paints (either liquid or powder) and agricultural fertilizers. These bags are usually made from strong materials such as woven polypropylene (PP) or multi-layer plastic to ensure durability and protection

Paint and fertilizer bag features:

Durability: Resistant to abrasion and punctures, making it suitable for heavy materials.

Moisture-proof: Prevents water or moisture from seeping in, which could affect the quality of the contents.

Versatile: Available in shapes and sizes to suit your storage and transportation needs.

Chemical resistance: Withstands interaction with chemicals found in paints or fertilizers.

Ease of Transport: Its design ensures easy storage and efficient transport.

Uses of paint and fertilizer bags:

Paint bags: Used for packaging powder or dry paints, such as cement paints or dry paste.

Fertilizer bags: Used for packaging organic or chemical fertilizers used in agriculture.

Types of materials used:

Woven polypropylene (PP): Ideal for bags requiring ventilation or high durability.

Multi-layer polyethylene: Provides additional protection against moisture and leakage.

Lined bags: Contain inner layers for added protection when handling liquids or delicate materials.

Its advantages:

It maintains the quality of stored or transported materials.

It is designed to withstand heavy weight and harsh conditions during transportation and storage.

It is environmentally friendly as it is made from recyclable materials.

Industrial Stretch Film

It is a flexible plastic film roll used to package and secure products, especially in industrial and commercial environments. It is usually made from linear low-density polyethylene (LLDPE) and is characterized by its ability to stretch and adhere to provide tight and secure packaging

Industrial Stretch Film Features:

High Flexibility: Stretches to tightly cover products without tearing.

Tear Resistance: Provides excellent protection during transportation and storage.

Transparency: Makes it easy to see the packaged contents without having to open the packaging.

Self-Adhesive: No additional adhesives are required, as the layers adhere to each other during packaging.

Insulation and Protection: Protects products from dust, moisture, and scratches.

Types of Industrial Stretch Wraps:

Manual Wrapping Rolls: Used for manual wrapping of small and medium loads.

Automated Wrapping Rolls: Used in production lines to wrap large quantities of products.

Transparent and Colored Films: Provide transparent or colored packaging options as needed.

Uses of Industrial Stretch Wraps:

Packaging goods on pallets to secure them during transportation and storage.

Protecting industrial products such as hardware, wood, and raw materials.

Packaging food products in factories to ensure cleanliness and protection.

Advantages:

Cost Reduction: Reduces the need for additional packaging materials.

Excellent Protection: Protects products from damage during handling.

Environmentally Friendly: Can be made from recyclable materials.

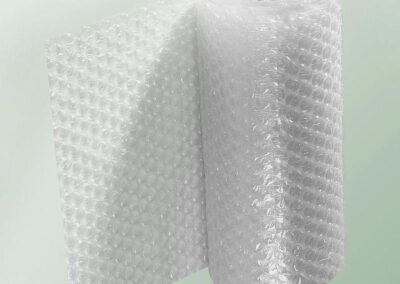

Air Bubble Rolls

Are rolls of plastic with air bubbles, primarily used to protect products during transportation and storage. This type of plastic is typically made of polyethylene (PE) and contains air bubbles within the film, providing an effective cushion of protection against shocks and scratches

Characteristics of Bubble Rolls:

Excellent Protection: Air bubbles provide high protection against shocks and scratches during transportation and storage.

Flexibility: They can be easily cut or trimmed to fit the size of the products being packaged.

Lightweight: They do not add extra weight to the packaged products, reducing shipping costs.

Durability: Bubbles improve durability due to the air pressure within them, which helps effectively absorb shocks.

Transparency: They provide a clear view of the contents packaged inside the roll.

Uses of bubble wrap:

Protecting products during transportation, such as electronic devices, glassware, and delicate products.

Commercial packaging: To protect products when shipped from the factory to the consumer.

Storage: They can be used to securely store fragile items.

Packaging in various industries: such as furniture, household items, or clothing that need to be protected from damage.

Advantages of Bubble Rolls:

Low cost: They provide a cheap and effective means of protection.

Ease of use: Products can be quickly and easily packaged using them.

Recyclability: They can be recycled in some cases, reducing the environmental impact.

Multi-layer protection: Multiple layers of bubble rolls can be used for greater protection.

Lamination Bags & Rolls

Lamination is the process of coating or covering the surface of materials (such as bags or rolls) with layers of different materials to provide additional protection and improve properties such as durability, moisture resistance, and gloss. These bags and rolls are primarily used in packaging to protect products from environmental factors

Characteristics of Lamination Bags and Rolls:

Additional Protection: Helps protect products from moisture, dirt, and dust.

Tear Resistance: Provides strong and durable packaging for products.

High-Quality Printing: High-quality logos and designs can be printed on laminated surfaces.

Multi-Layer: Different layers of materials such as polyethylene, polypropylene, or aluminum are used.

Semi-Transparent or Fully Transparent: Allows contents to be clearly visible.

Uses of laminating bags and rolls:

Packaging food products such as cereals, biscuits, and beverages.

Packaging medical products and cosmetics.

In packaging of electronics industries.

Tarpaulin

Plastic tarpaulin is a type of plastic widely used in many industries due to its diverse properties, such as durability, water resistance, ease of cleaning, and flexibility. Plastic tarpaulin is made from polymeric materials such as polyethylene or polypropylene and can be plain or patterned, depending on the needed application.

Tarpaulin Features:

1. Waterproof: Plastic tarpaulin is completely waterproof, making it ideal for use in areas requiring moisture or water resistance, such as awnings and protective covers.

2. Versatile: It can be used in many applications such as table covers, tents, floor coverings, and packaging.

3. Easy to clean: The tarpaulin can be easily cleaned with soap and water, making it suitable for use in environments that require frequent cleaning.

4. UV Resistant: Some types of plastic tarpaulins have high UV resistance, making them ideal for use in areas exposed to the sun.

5. Durable: Tarpaulins have a high resistance to tearing and damage, ensuring they last for a long time.

6. Lightweight: Plastic tarpaulins are lightweight compared to other materials, making them easy to transport and store.

Types of tarpaulins:

1. Regular tarpaulin: Used for simple applications such as protective covers for equipment or floors.

2. Decorative linoleum: It has patterns or decorative layers and is used in the manufacture of furniture such as table covers or furniture in commercial places.

3. Antibacterial linoleum: Contains additives that prevent bacterial growth and is used in areas that require sterilization, such as hospitals and kitchens.

Uses:

• Packaging: It is used to package products to protect them from environmental factors.

• Furniture and decoration: It is used in the manufacture of plastic covers and tablecloths for tables and chairs.

• Construction: Used as covers to protect surfaces from water or dirt.

• Tents and Awnings: Used in the manufacture of tents and awnings due to its water and weather resistance.

• Agriculture: Used as floor coverings in greenhouses and farms.

Tarpaulin is a versatile material with multiple advantages that make it the ideal choice for many applications in our daily lives and industry.